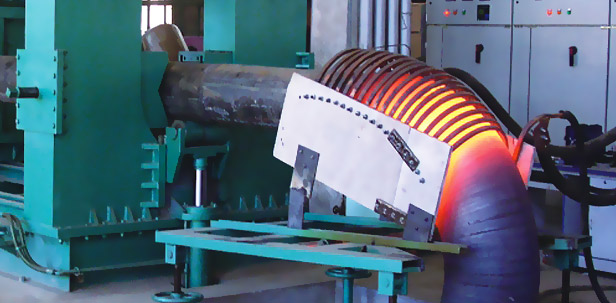

Insulation elbow

Insulation elbows are widely used in liquid and gas transportation pipeline networks, chemical pipeline insulation projects in petroleum, chemical, central heating networks, central air conditioning ventilation pipelines, and municipal facilities construction projects. Insulation pipes (including elbows, tees and crosses) are directly buried prefabricated insulation pipes with good insulation performance, safety and reliability, and low engineering construction price.

It effectively solves the problems of heat preservation of heat preservation pipes, heat preservation of bent parts, sliding lubrication, waterproofing and anticorrosion of exposed pipe ends and bends in various pipeline projects such as heating, cooling, heating, electric power, and chemical engineering. It not only has advanced technology and practical performance that traditional trenches and overhead pipelines are difficult to match, but also has significant social and economic benefits, and the heat preservation straight pipe is turned.

The polyurethane insulation steel pipe production workshop should be tidy and dust-free as much as possible. The environment and temperature are controlled at about 28 degrees. The polyurethane rigid foam of the polyurethane insulation steel pipe produced at this temperature has a high closed cell rate, which can reach more than 98%, which fully guarantees the insulation capacity of the polyurethane insulation steel pipe.

During the construction of the insulation elbow, it should be avoided to soak in groundwater and rainwater. If the end is accidentally immersed in water, it should be dried before connecting the jacket.

The pipes should be stored in a flat area, neatly stacked, and the stacking height should be less than 1.5 meters.

- TEL- +86-15226756063

- EMAIL- czlsg@163.com

- ADD- Yanta Road Industrial Area, Yanshan,Hebei.